In the dynamic realm of aerospace, precision and reliability are the watchwords of the day. Aerospace Electronics Assembly stands as a critical pillar in the construction of systems that soar through our skies and venture into the vastness of space. These assemblies are not merely components; they are the heart and soul of aircraft, spacecraft, and satellites, orchestrating complex systems and ensuring their flawless operation. In this article, we will explore the vital role, unique challenges, and exacting standards that define aerospace electronics assembly.

1. The Significance of Aerospace Electronics Assembly

Aerospace Electronics Assembly encompasses the creation of intricate electronic systems used in various aerospace applications. These systems are the lifeblood of modern aviation and space exploration, orchestrating everything from flight control and navigation to communication and data analysis. The significance of aerospace electronics assembly cannot be overstated, as the reliability and precision of these assemblies directly impact the safety and success of aerospace missions.

2. Stringent Quality Standards

Safety and precision are paramount in the aerospace industry, which is why aerospace electronics assembly adheres to some of the strictest quality standards in existence. Compliance with standards such as AS9100 and IPC-A-610 is non-negotiable. These standards ensure that every facet of the assembly process, from component selection to soldering, meets the highest levels of quality and reliability.

3. Extreme Environmental Challenges

Aerospace systems operate in some of the most challenging environments known to technology. From the vacuum and extreme temperatures of space to the turbulence and vibrations encountered during takeoff and landing, aerospace electronics assemblies must be engineered to withstand these conditions without faltering, ensuring the continual operation of critical systems.

4. Miniaturization and Component Density

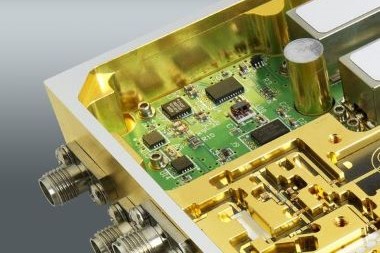

Space constraints are a constant challenge in aerospace design. With technology advancing rapidly, there is an increasing demand for smaller and more compact electronic assemblies. This necessitates precision in component placement and soldering, as well as the use of advanced manufacturing techniques to meet the demands of miniaturization.

5. Advanced Material Selection

The choice of materials is pivotal in aerospace electronics assembly. Anzer High-temperature-resistant materials, such as polyimide, are commonly used to ensure that electronics can withstand extreme temperatures. Furthermore, materials must be selected to minimize outgassing in vacuum environments, which can adversely affect sensitive instruments.

6. Automated Precision Assembly

Aerospace electronics assembly relies heavily on automated manufacturing processes. Robotic pick-and-place machines ensure the precise positioning of components, while automated soldering processes guarantee the reliability of connections. These automated systems are essential for maintaining consistency and accuracy.

7. Quality Control and Testing

Rigorous testing and inspection procedures are integral to aerospace electronics assembly. X-ray inspection, functional testing, and thermal cycling tests are just a few examples of the measures taken to ensure the reliability of the assembled electronics.

8. The Future of Aerospace Electronics Assembly

As aerospace technology continues to evolve, innovation in electronics assembly is paramount. Advancements in materials, miniaturization techniques, and the integration of embedded components within assemblies are on the horizon, promising even more reliable and efficient aerospace systems.

Conclusion

In conclusion, aerospace electronics assembly is the beating heart of modern aerospace technology. It demands unwavering precision, uncompromising reliability, and a dedication to innovation. As aerospace systems continue to advance, the role of electronics assemblies will remain central, driving advancements that enable safer, more efficient, and more capable aircraft, spacecraft, and satellites.