In the realm of industrial equipment, a practice often overlooked yet critical for maintaining seamless operations involves the routine inspection of magnets. This seemingly mundane task is, in fact, the unsung hero preventing costly downtimes and ensuring the long life of machinery.

Introduction

Far from being just a checkbox in your maintenance routine, magnet inspection acts as a shield against unforeseen equipment failures. In this discussion, we’ll delve into the fundamentals of magnet inspection, explore the tools and technologies at your disposal, and understand why proactive maintenance is the key to sustained operational excellence.

Basics of Magnet Inspection

Before we explore the tools and technologies, it’s essential to grasp why magnets require regular check-ups. Despite their durability, magnets can succumb to wear and tear over time. Neglecting timely inspections could result in decreased efficiency, weakened magnetic strength, and potential damage to surrounding components.

Common Magnet Inspection Tools

Magnetic Field Meters: These handheld devices serve as your eyes into the magnetic field, helping measure strength and identify irregularities.

Gaussmeters: Reliable companions in gauging magnetic flux density. A drop in Gauss readings can signal potential magnet deterioration.

Visual Inspection Techniques: Sometimes, the naked eye is the best inspector. Look for physical signs such as cracks, chips, or uneven surfaces on the magnet.

Advanced Technologies in Magnet Inspection

Embrace modernity with advanced technologies like magnetic imaging. This forward-thinking approach provides a comprehensive view of your magnets, leaving no room for hidden issues. Integrating such technologies enhances the accuracy of inspections, ensuring a thorough analysis of the magnetic landscape.

Step-by-Step Guide for Magnet Inspection

- Setting Up for Inspection: Ensure a controlled environment and have your inspection tools ready.

- Conducting the Inspection: Follow a systematic process, checking every nook and cranny for potential issues.

- Interpreting Results: Understanding the data is crucial. Know what different readings mean for your equipment’s health.

Importance of Regularity in Inspections

Consider magnet inspection as a health check for your machinery. Regular inspections provide an early warning system, allowing you to address issues before they escalate. This proactive approach not only saves you from unexpected downtimes but also significantly cuts down on maintenance costs in the long run.

Case Studies in Effective Magnet Inspection

Let’s move from theory to practicality. Numerous companies have reaped the benefits of diligent magnet inspection. Case studies reveal how specific tools and technologies played a pivotal role in identifying and rectifying potential issues, highlighting the tangible advantages of a well-executed inspection strategy.

Training and Education on Magnet Inspections

Knowledge is power. Educate your maintenance teams on proper inspection techniques, empowering them to identify and address issues effectively. Various resources and training programs are available to enhance your team’s skills, ensuring they are well-equipped for the task at hand.

Troubleshooting and Problem Resolution

Even with regular inspections, issues might arise. This section delves into common problems detected during inspections and provides actionable solutions. From addressing decreased magnetic strength to dealing with physical damage, we’ve got you covered.

Conclusion

In the dynamic world of industrial maintenance, magnet inspection stands as a beacon of preventive care. By incorporating the right tools, staying updated on technologies, and fostering a culture of regular inspections, you not only ensure the health of your equipment but also contribute to the overall efficiency and reliability of your operations.

Additional Resources

Explore further with our recommended readings on magnet inspection. Whether you’re a seasoned professional or a newcomer to the field, these resources will enhance your understanding and help you stay at the forefront of effective equipment maintenance.

In the journey of equipment longevity, magnet inspection is your steadfast ally. Embrace it, optimize it, and watch as your machinery performs at its peak, keeping your operations seamlessly on track.

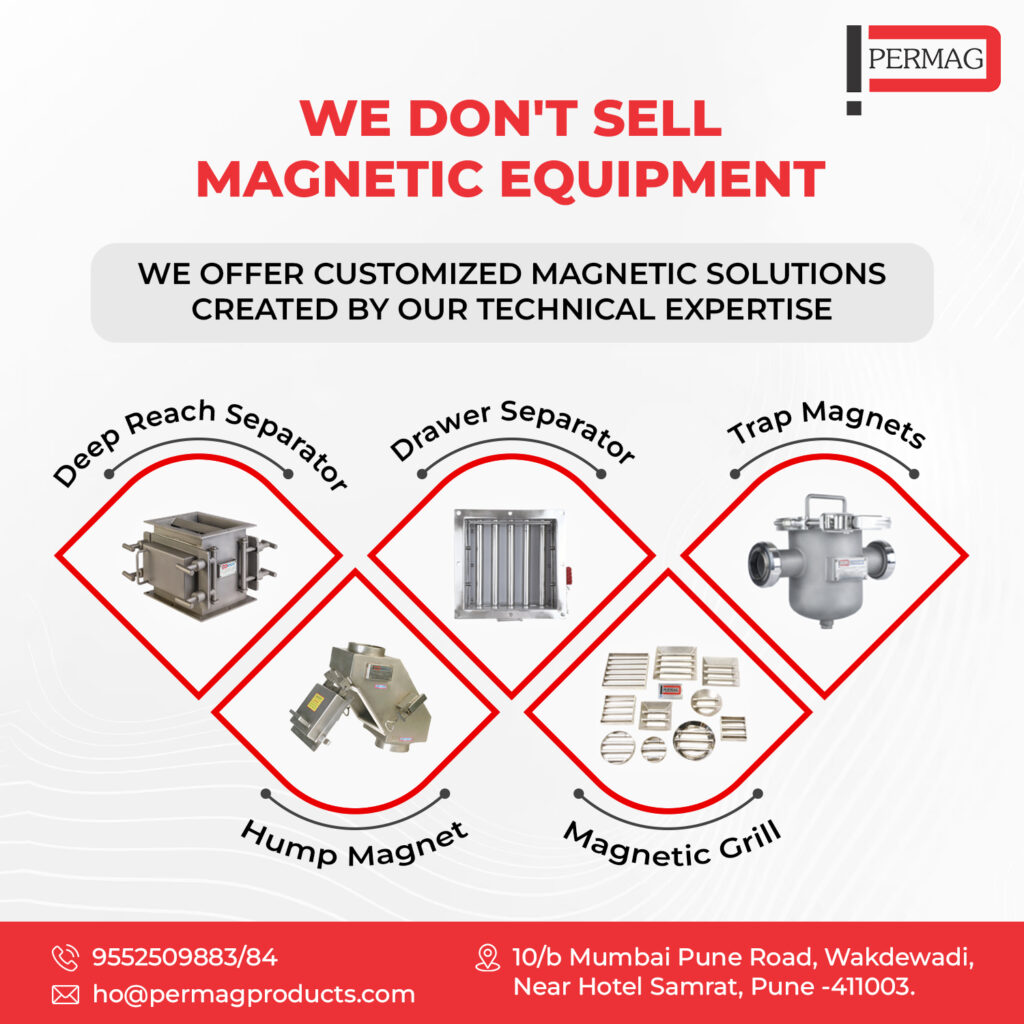

PERMAG Products is a leading supplier of drawer separator, and we are committed to providing our customers with the highest quality products available on the market. Thanks to our state-of-the-art manufacturing process, we are able to produce magnetic rods that meet the most stringent quality standards.